Products

CHILLERS

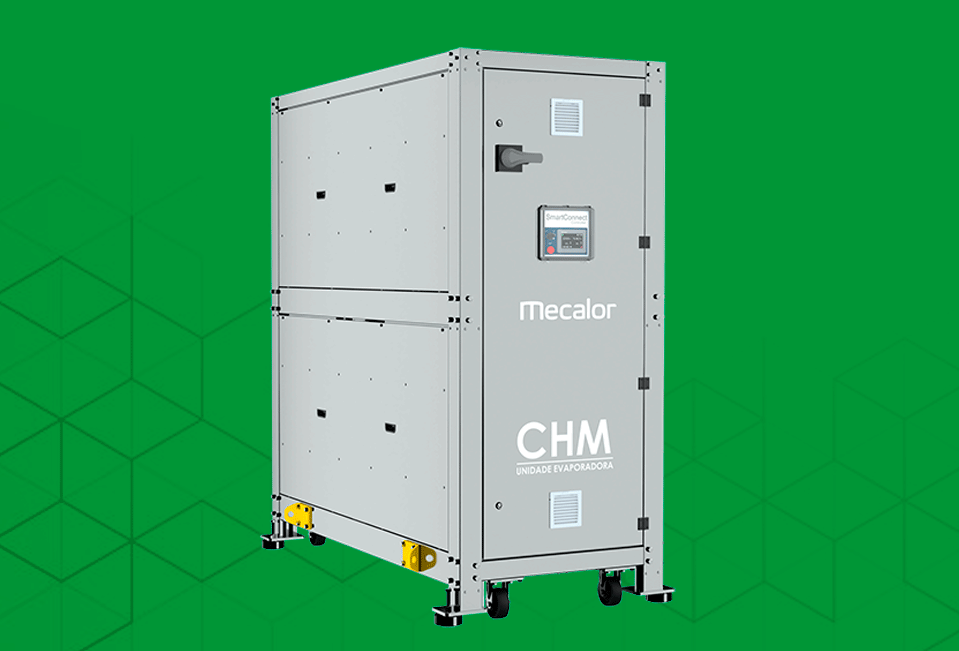

CHM Multi-Stage Modular System

- Ensures redundancy in the cooling process, helping prevent unwanted interruptions and downtime in industrial operations.

- Modular structure allows for scalability, enabling production to grow by adding new units, expanding capacities up to 3,600 kW.

- Individual control per module optimizes energy consumption according to operational demands, providing significant savings on the electric bill.

- Compact design minimizes occupied space and reduces installation complexity.

Compact Chiller MSA

- The most complete version with PLC control ensures maximum efficiency and performance.

- Compact design with built-in tank and pump.

- Modular concept allows combining multiple units to reach up to 3,600 kW.

- With this new line, the standardized cases for modular installations result in improved agility, reduced setup and installation times, and lower construction costs.

Compact Chiller MSW

- This chiller line, with capacities ranging from 5,000 to 75,000 kcal/h, has water condensation and is recommended for installation in environments with high temperatures or lack of air circulation. In this type of chiller, the plate condenser needs to be cooled with industrial water. A water filter is incorporated into the equipment and protects the gear exchanger.

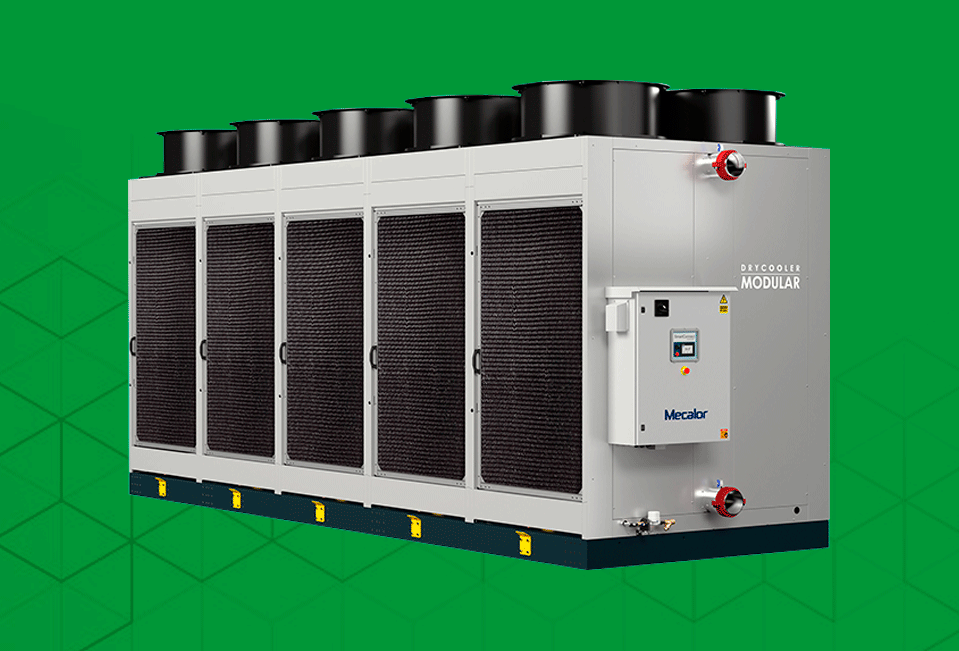

DryCooler Aludry Modular

- DryCooler is the eco-friendly replacement for conventional cooling towers.

- Minimizes bacterial proliferation in water cooling systems.

- Reduces water consumption by up to 90% compared to conventional systems.

- Promotes energy efficiency due to lower thermal inertia in the process.

- Ensures lower operating and maintenance costs.

- In addition, the reduced monthly expenses, setup, water, and electricity use directly impact the expenses for the environment.

Hospital Chiller IHA

- Approved by medical equipment manufacturers

- The most complete version with PLC control ensures operations that are highly reliable, user-friendly, and efficient, ensuring no interruptions during surgeries, tests, and imaging procedures.

- It was designed to allow for redundancy with two independent sets of refrigeration circuits, a primary and a secondary system, each equipped with compressors approved by the top medical equipment manufacturers.

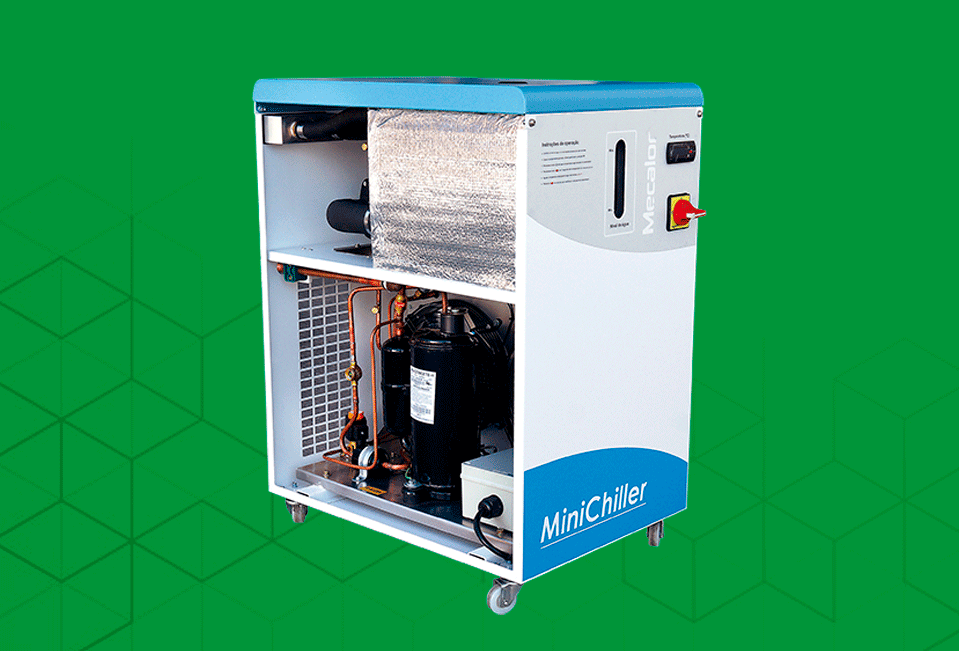

Mini Chiller MCA

- An advanced series, the MCA unit supplies from 2,000 to 50,000 kcal/h in one compact solution, and is ideal for industrial water cooling applications, such as laboratory equipment.